PRE-STRESSED LINTELS - COMPOSITE LINTELS

Pre-stressed 1- and 2-layer lintels rarely have to support any loads, as the back-up walls represent the bearing structure for a roof or a floor division.

By using TB-Trough instead of traditional roofing felt over brick lintels, an improved strength of the brick beams is achieved.

Pre-stressed lintels guarantee that:

- No displacement cracks appear through support

- A lintel never lays or presses on window and door frames

The crossbars - on which the brick beams lay - must be on both sides at least 1/2 bricks.

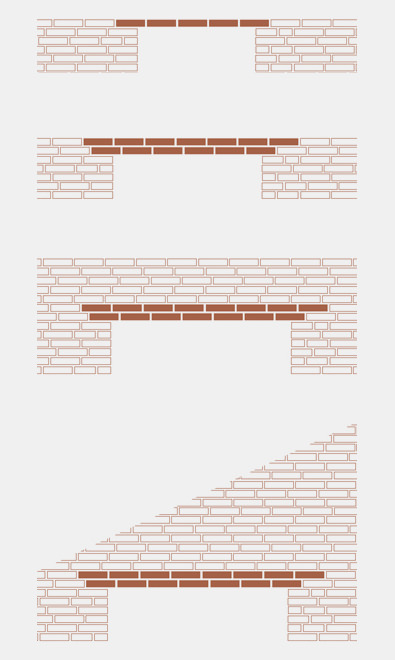

1-LAYER PRE-STRESSED BRICK LINTELS

Up to 12 bricks (2,870 mm) long.

Used for light distances of maximum 2,630 mm.

2-LAYER PRE-STRESSED BRICK LINTELS

Up to 22 bricks (5,270 mm) long.

Used for light distances of maximum 5,040 mm.

MASONRY ON PRE-STRESSED COMPOSED BRICK LINTELS

The existing masonry doesn't represent a load for the pre-stressed front lintel, as long as no masonry paper is inserted in the length joints, as the lintel and the masonry form a composed brick beam. On the contrary, it relieves, because it divides the load.

- The number of the masonry layers lying over the lintel is thus important for the calculation of the correct lintel size.

- For the gable surface it's important to consider the minimum number of layers, as well as the maximum.

The sizing and static calculation are included in the price, in the case of pre-stressed lintels in standard format, from Carlsberg Bjælker™.

SOLUTIONS WITH BRICK LINTELS

Standard brick lintels in many widths for fronts. The pre-stressed brick lintels on the front simplify the work on the construction site and optimize quality, because pre-stressed brick lintels have a greater rigidity, and thus a greater supporting effect, preventing displacement cracks caused by support. Likewise, it prevents the lintel from pressing on the window or the door frame. Front lintels are produced in various widths and of the same bricks used for the rest of the masonry.

Standard brick lintels in many widths for back=up masonry. The Carlsberg pressing technique offers strong advantages, as pre-stressed lintels have a higher rigidity and load capacity, thus preventing displacement cracks during support. Likewise, it prevents the lintel from pressing on the window or the door frame. The sizing and static calculation are included in the price, in the case of pre-stressed lintels with standard sizes, from Carlsberg Bjælker™.

Double layered brick lintels with glazed front. For the front double layered pre-stressed lintels with drip edge 4.31-m long have been used. The bricks are glazed on the front and underneath, while the milled drip edge is also glazed. In the window niches glazed shaped bricks are embedded as window sills.

REQUIREMENTS, CALCULATIONS AND QUOTES

Do you need advice, or would you like to receive a quotation for your estimate? Kindly contact our consultants or send us your material.

If you're sending us sketches in electronic format, please make sure that:

- The material is in PDF format, the dimensions are mentioned on the sketch, and any other additional sketches may be sent in DWG format.

- The data should contain a plan, a sectional drawing and a façade sketch.

- Other data may be sent in an e-mail, or attached in a Word file.

Kindly send your materials or questions to:

E-mail: carlsberg@randerstegl.dk

Phone +45 87 11 45 11

Fax +45 87 11 45 10

SKETCHES ON PAPER

Sketches on paper may be sent via post to the following address:

Randers Tegl

Carlsberg Bjælker

Tindbækvej 16

DK-8830 Tjele

Denmark