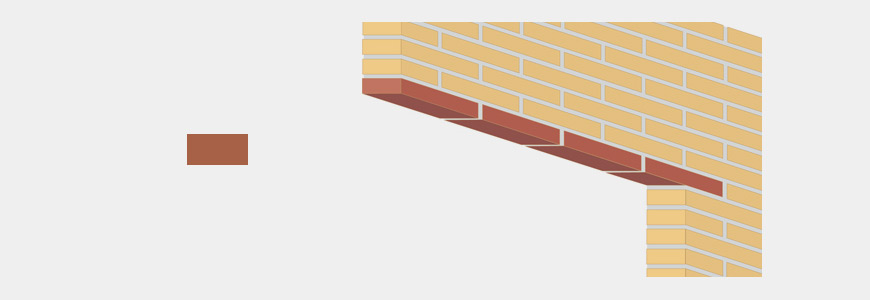

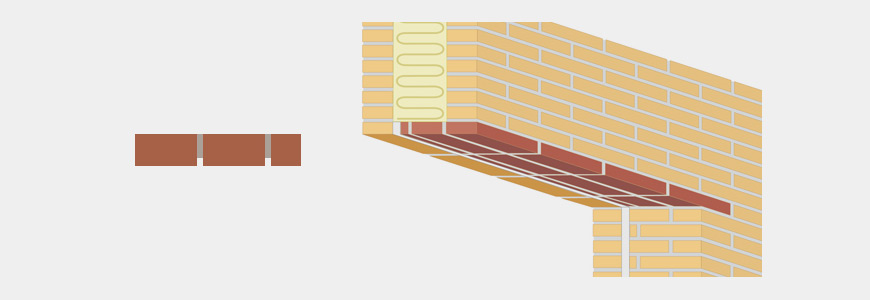

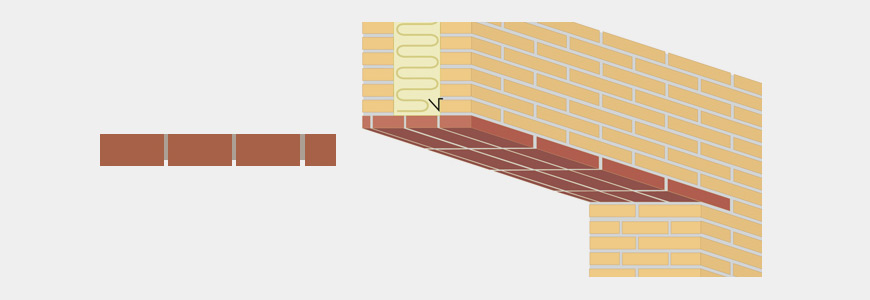

1-LAYER LINTELS

PRE-STRESSED 1-LAYER LINTELS ARE PRODUCED ACCORDING TO STANDARDS, IN DANISH NORMAL FORMAT, IN RUNNING BOND.

Sizing

Carlsberg Bjælker's-specific calculation, according to applicable standards. Sizing, static calculations and goods declarations are included in the price.

Dimensions for pre-stressed 1-layer lintels

They are produced up to a length of 12 bricks - 2,870 mm - for light widths of maximum 2,630 mm, because the shortest crossbar should sit on 1/2 brick at both ends of the brick beam.

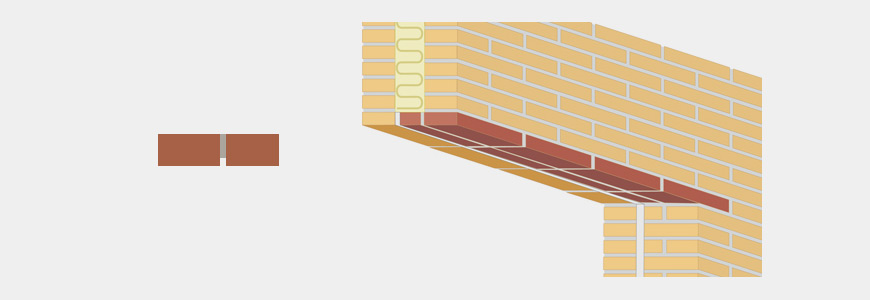

BACK-UP MASONRY LINTELS

They have scratched out joints and are made of extruded or machine-processed ”hand-made” back-up masonry bricks.

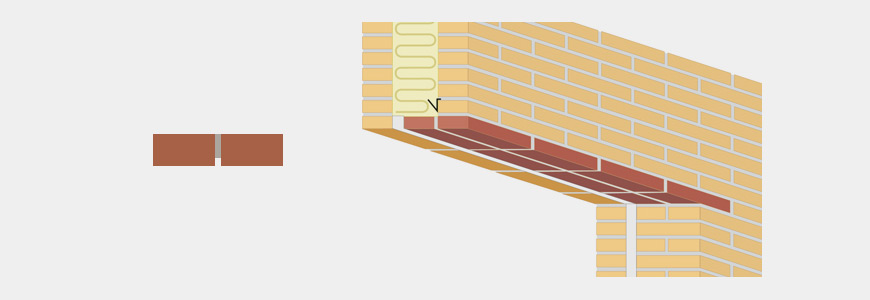

11 cm lintel

It's 11 cm wide and is made of extruded or machine-processed ”hand-made bricks”. It is produced in a length of 12 bricks, for light openings of maximum 2,410 mm.

Reinforcement: 2 pieces, 5 mm thick, stainless or black tension wires.

Sizing: Masonry project programme Version 3.0

Normally used over door and window openings.

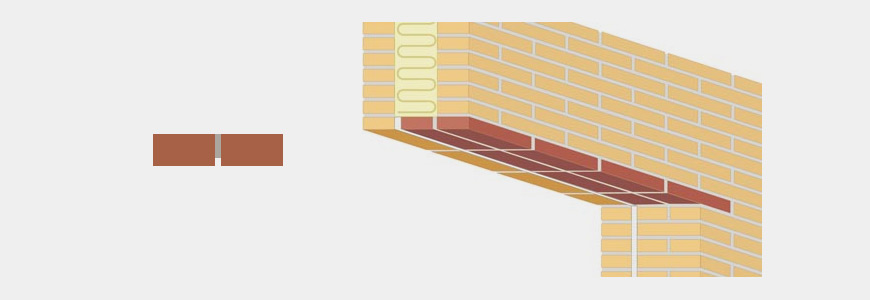

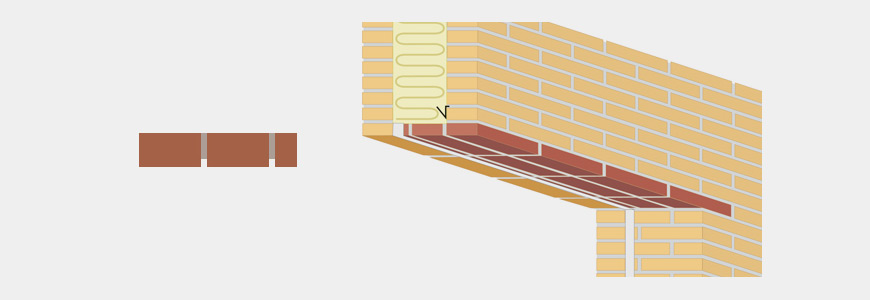

17 cm lintel

It's 17-cm wide and is made of extruded or machine-processed ”hand-made bricks”. It's produced in a length of 12 bricks tops, for light openings of maximum 2,410 mm.

Reinforcement: 3 pieces, 5-mm thick, stainless or black tension wires.

Sizing: Masonry projection programme version 3.0

Normally used over door and window openings.

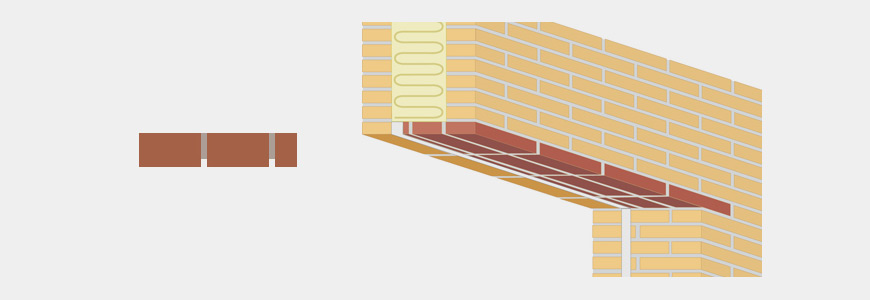

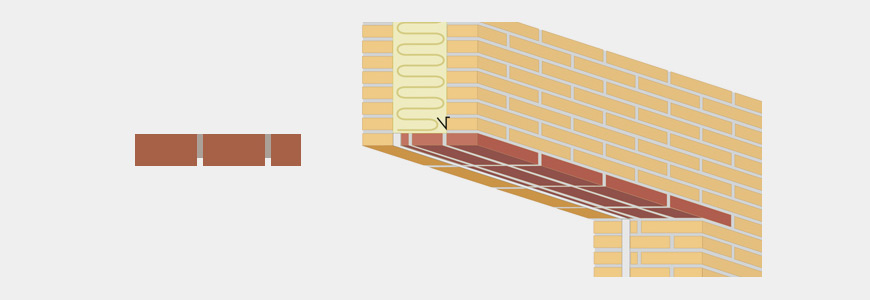

20 cm lintel

It's 20-cm wide and is made of extruded or machine-processed ”hand-made bricks”. It's produced in a length of 12 bricks tops, for light openings of maximum 2,410 mm.

Reinforcement: 3 pieces, 5-mm thick, stainless or black tension wires.

Sizing: Masonry projection programme version 3.0

Normally used over door and window openings.

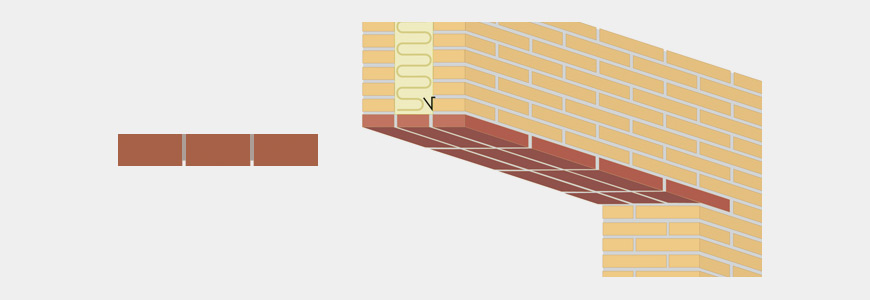

23 cm lintel

It's 23-cm wide and is made of extruded or machine-processed ”hand-made bricks”. It's produced in a length of 12 bricks tops, for light openings of maximum 2,410 mm.

Reinforcement: 4 pieces, 5-mm thick, stainless or black tension wires.

Sizing: Masonry projection programme version 3.0

Normally used over door and window openings in wide or half-brick back-up walls.

27 cm lintel

It's 27-cm wide and is made of extruded or machine-processed ”hand-made bricks”. It's produced in a length of 12 bricks tops, for light openings of maximum 2,410 mm.

Reinforcement: 5 pieces, 5-mm thick, stainless or black tension wires.

Sizing: Masonry projection programme version 3.0

Normally used over door and window openings in wide or half-brick back-up walls.

29 cm lintel

It's 29-cm wide and is made of extruded or machine-processed ”hand-made bricks”. It's produced in a length of 12 bricks tops, for light openings of maximum 2,410 mm.

Reinforcement: 5 pieces, 5-mm thick, stainless or black tension wires.

Sizing: Masonry projection programme version 3.0

Normally used over door and window openings in wide or half-brick back-up walls.

FRONT LINTELS

With back joints made of extruded or machine-processed ”hand-made bricks”.

Front lintels made of machine-processed ”hand-made bricks” are always made of the same brick part used on for the facade masonry. They are made with the ”water-struck bead”.

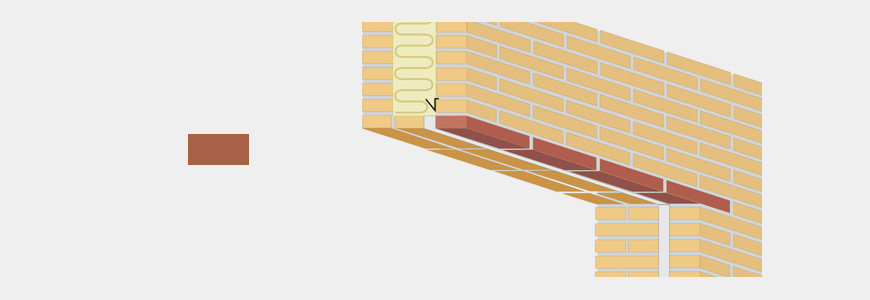

11 cm lintel

It's 11 cm wide and is made of extruded or machine-processed ”hand-made bricks”.

It is produced in a length of 12 bricks, for light openings of maximum 2,410 mm.

Reinforcement: 2 pieces, 5 mm long stainless tension wire.

Sizing: Masonry project program version 3.0

Normally mounted over door and window openings, in buildings completely made of bricks and in buildings with element back-up walls.

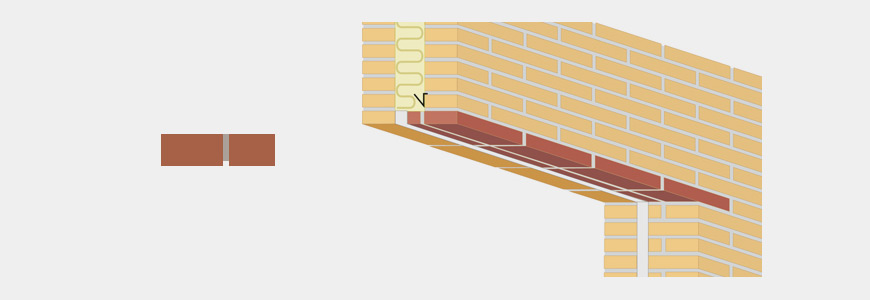

17 cm lintel

It is 17 cm wide and is made of extruded or machine-processed ”hand-made bricks”. It's produced in a length of 12 bricks, for measures of capacity of maximum 2,410 mm.

Front lintels made of machine-processed ”hand-made bricks” are always made of the same brick part used for the facade masonry.

Reinforcement: 3.5-long pieces, stainless or black tension wires.

Sizing: Masonry project programme version 3.0

Normally mounted over door and window openings, in buildings completely made of bricks and in buildings with element back-up walls. They can be used for solid buildings with 3 front sides.

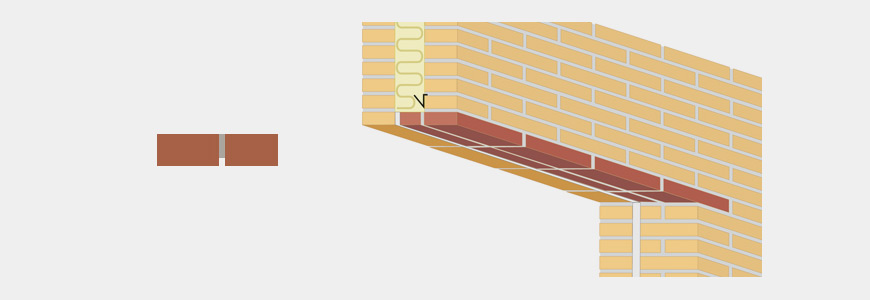

20 cm lintel

It's 20 cm wide and is made of extruded or machine-processed ”hand-made bricks”. It's produced in a length of 12 bricks, for measures of capacity of maximum 2,410 mm.

Front lintels made of machine-processed ”hand-made bricks” are always made of the same brick part used for the facade masonry.

Reinforcement: 3.5-long pieces, stainless or black tension wires.

Sizing: Masonry project programme version 3.0

Normally mounted over door and window openings, in buildings completely made of bricks and in buildings with element back-up walls. They can be used for solid buildings with 3 front sides.

23 cm lintel

It's 23-cm wide and is made of extruded or machine-processed ”hand-made bricks”. It's made of header brick. It's produced in a length of 12 bricks tops, for measures of capacity of maximum 2,410 mm.

Front lintels made of machine-processed ”hand-made bricks” are always made of the same brick part used on for the facade masonry.

Reinforcement: 4.5-long pieces, stainless or black tension wires.

Sizing: Masonry projection programme version 3.0

Normally mounted over door and window openings, in buildings completely made of bricks and in buildings with element back-up walls. They can be used for massive buildings with 3 front sides.

27 cm lintel

It's 27-cm wide and is made of extruded or machine-processed ”hand-made bricks”. It's produced in a length of 12 bricks tops, for measures of capacity of maximum 2,410 mm.

Front lintels made of machine-processed ”hand-made bricks” are always made of the same brick part used on for the facade masonry.

Reinforcement: 5.5-long pieces, stainless or black tension wires.

Sizing: Masonry projection programme version 3.0

Normally mounted over door and window openings, in buildings completely made of bricks and in buildings with element back-up walls. They can be used for solid buildings with 3 front sides.

29 cm lintel

It's 29-cm wide and is made of extruded or machine-processed ”hand-made bricks”. It's produced in a length of 12 bricks tops, for measures of capacity of maximum 2,410 mm.

Front lintels made of machine-processed ”hand-made bricks” are always made of the same brick part used on for the facade masonry.

Reinforcement: 5.5-long pieces, stainless or black tension wires.

Sizing: Masonry projection programme version 3.0

Normally mounted over door and window openings, in buildings completely made of bricks and in buildings with element back-up walls. They can be used for massive buildings with 3 front sides.

35 cm lintel

It's 35-cm wide and is made of extruded or machine-processed ”hand-made bricks”. It's produced in a length of 12 bricks tops, for measures of capacity of maximum 2,410 mm.

Front lintels made of machine-processed ”hand-made bricks” are always made of the same brick part used on for the facade masonry.

Reinforcement: 6.5-long pieces, stainless or black tension wires.

Sizing: Masonry projection programme version 3.0

Normally mounted over door and window openings, in buildings completely made of bricks and in buildings with element back-up walls. They can be used for garage doors with 3 front sides.

41 cm lintel

It's 41-cm wide and is made of extruded or machine-processed ”hand-made bricks”. It's produced in a length of 12 bricks tops, for measures of capacity of maximum 2,410 mm.

Front lintels made of machine-processed ”hand-made bricks” are always made of the same brick part used on for the facade masonry.

Reinforcement: 8.5-long pieces, stainless or black tension wires.

Sizing: Masonry projection programme version 3.0

Normally mounted over door and window openings, in buildings completely made of bricks and in buildings with element back-up walls. They can be used for bricked buildings with 3 front sides.

Pre-stressed 1-layer lintels are produced in the mentioned standard versions. The sizing, static calculation and goods declaration are included in the price.

Lintels with Monk bond, different bond or different widths are calculated individually, according to each case.

For technical information and calculations please contact:

Carlsberg Bjælker A/S

E-mail carlsberg@randerstegl.dk

Phone: +45 87 11 45 11

Fax: +45 87 11 45 10