BACK-UP BRICKS

THESE BRICKS ARE PRODUCED IN ORDER TO BE USED IN SUPPORTING AND NON-SUPPORTING INDOOR STRUCTURES

Format: Danish normal format and horizontal format, DS 414.

The technical specifications correspond to those of facing bricks, for similar designs.

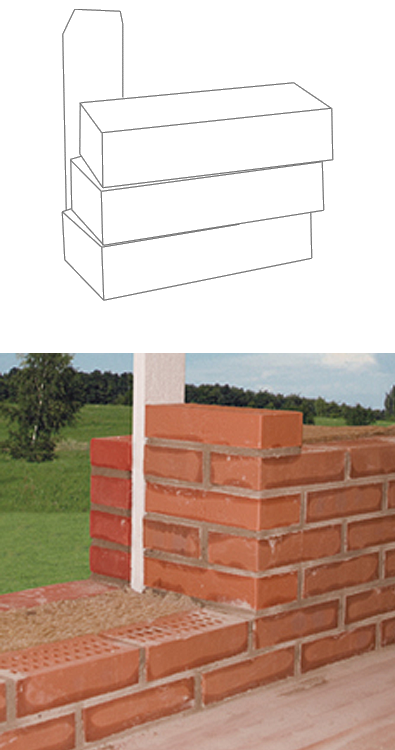

27 CM-INTERLOCKING TILES FOR BACK-UP MASONRY

Bricks with an additional 4-cm length, which simplify the process of building door and window recesses in buildings with 190-mm insulation.

Extruded bricks with holes and water-struck aspect for plastering. Also appropriate for the bottom of window openings.

Call us to get a sample!

WATER-STRUCK BACK-UP BRICKS

These bricks are produced in order to be used in supporting and non-supporting indoor structures

Format: Danish normal format and horizontal format, DS 414.

The technical specifications correspond to those of facing bricks, for similar designs.