3-LAYER BEAMS

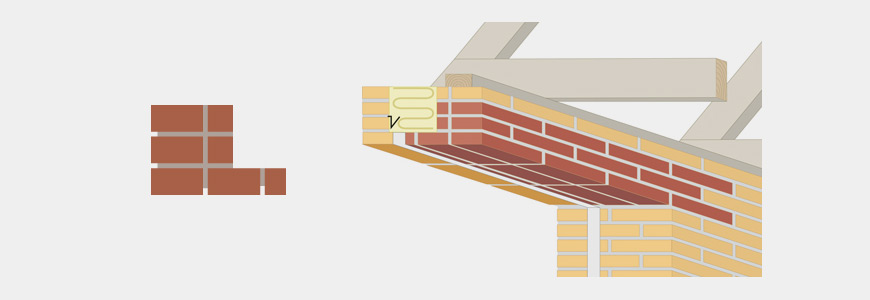

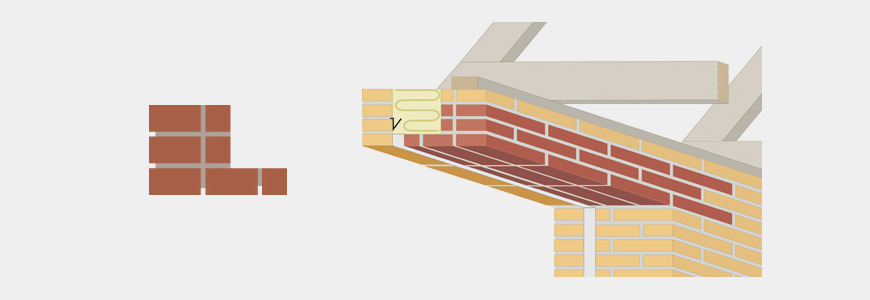

PRE-STRESSED BRICK BEAMS ARE PRODUCED ACCORDING TO STANDARDS, IN DANISH NORMAL FORMAT, IN RUNNING BOND.

Sizing

Carlsberg Bjælkers-specific calculation, according to applicable standards. Sizing, static calculations and goods declarations are included in the price.

Dimensions for pre-stressed 3-layer brick beams

They are produced up to a length of 27 bricks - 6.480 mm - for light widths of maximum 6.240 mm, because the shortest crossbar should sit on 1/2 brick at both ends of the brick beam.

3-LAYER BRICK BEAMS FOR BACK-UP MASONRY AND FAÇADES

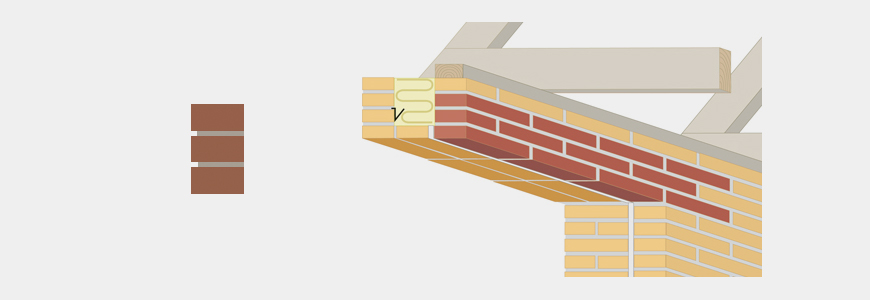

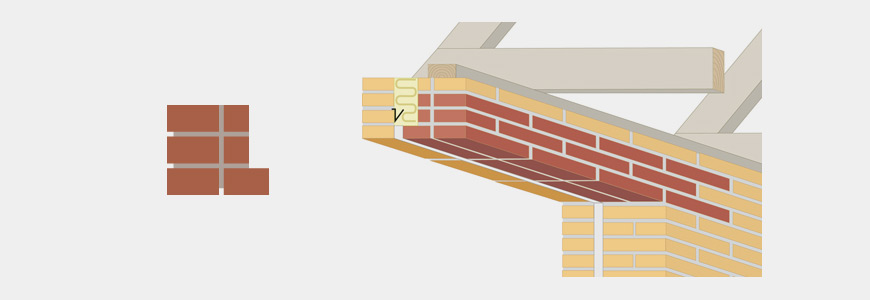

11 cm (3N)*-masonry beams

Produced with an extruder, or machine-processed ”hand-made bricks”.

Machine-processed ”hand-made” brick beams for visible masonry are always produced of brick of the same part with which the façade has been bricked.

They are produced as a standard in a length of 27 bricks, for light openings of maximum 6,240 mm.

They are used for façades and back-up masonry, where a composed brick lintel does not provide enough support.

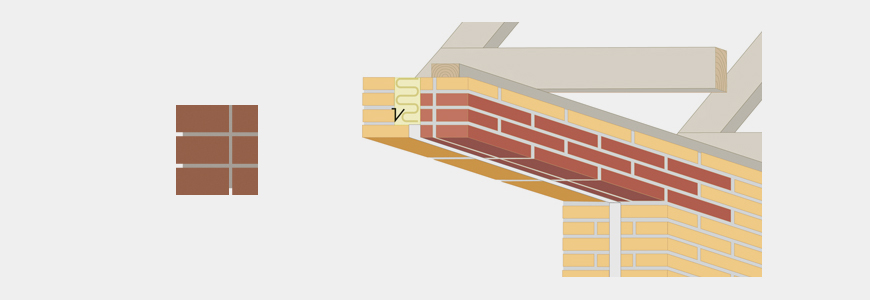

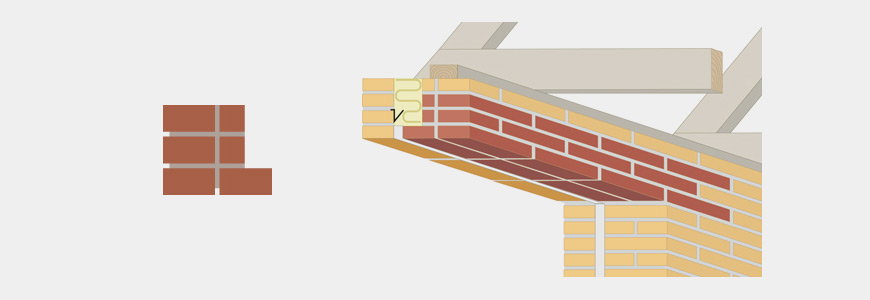

17 cm (3B)*-masonry beams

Produced with an extruder, or machine-processed ”hand-made bricks”.

Machine-processed ”hand-made” brick beams for visible masonry are always produced of brick of the same part with which the façade has been bricked.

They are produced as a standard in a length of 27 bricks, for light openings of maximum 6,240 mm.

They're used for fronts and back-up masonry, where a composed brick lintel didn't provide enough support.

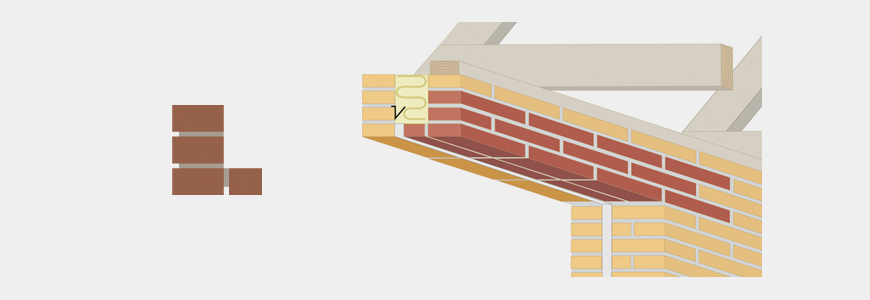

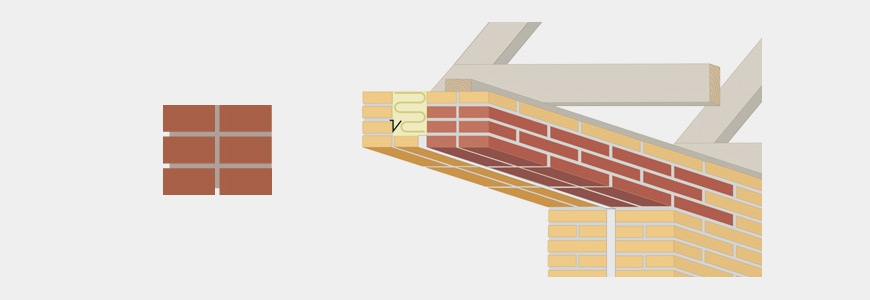

20/2 x 11 cm (20/2N)-masonry beams

Produced with an extruder, or machine-processed ”hand-made bricks”.

Machine-processed ”hand-made” brick beams for visible masonry are always produced of brick of the same part, with which the front has been bricked.

They're produced as a standard in a length of 27 bricks tops, for light openings of maximum 6,240 mm.

They're used for fronts and back-up masonry, where a composed brick lintel didn't provide enough support.

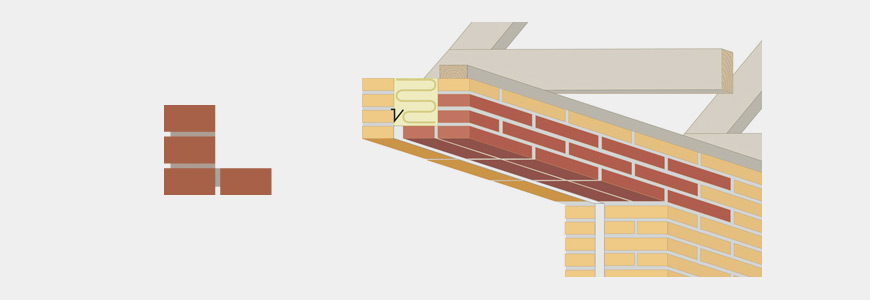

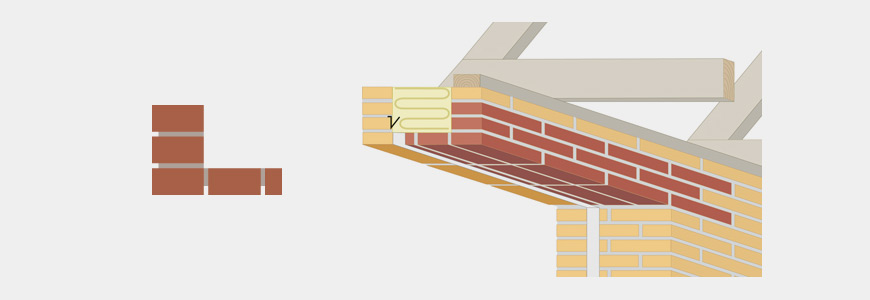

23/2 x 11 cm (H/2N)*-masonry beams

Produced with an extruder, or machine-processed ”hand-made bricks”.

Machine-processed ”hand-made” brick beams for visible masonry are always produced of brick of the same part, with which the front has been bricked.

They're produced as a standard in a length of 27 bricks tops, for light openings of maximum 6,240 mm.

They're used for fronts and back-up masonry, where a composed brick lintel didn't provide enough support.

20/2 x 17 cm (20/2B)*-masonry beams

Produced with an extruder, or machine-processed ”hand-made bricks”.

Machine-processed ”hand-made” brick beams for visible masonry are always produced of brick of the same part, with which the front has been bricked.

They're produced as a standard in a length of 27 bricks tops, for light openings of maximum 6,240 mm.

They're used for fronts and back-up masonry, where a composed brick lintel didn't provide enough support.

23/2 x 17 cm (H/2B)*-masonry beams

Produced with an extruder, or machine-processed ”hand-made bricks”.

Machine-processed ”hand-made” brick beams for visible masonry are always produced of brick of the same part, with which the front has been bricked.

They're produced as a standard in a length of 27 bricks tops, for light openings of maximum 6,240 mm.

They're used for fronts and back-up masonry, where a composed brick lintel didn't provide enough support.

23 cm (3H)*-masonry beams

Produced with an extruder, or machine-processed ”hand-made bricks”.

Machine-processed ”hand-made” brick beams for visible masonry are always produced of brick of the same part, with which the front has been bricked.

They're produced as a standard in a length of 27 bricks tops, for light openings of maximum 6,240 mm.

They're used for fronts and back-up masonry, where a composed brick lintel didn't provide enough support.

27/2 x 11 cm (27/2N)*-masonry beams

Produced with an extruder, or machine-processed ”hand-made bricks”.

Machine-processed ”hand-made” brick beams for visible masonry are always produced of brick of the same part, with which the front has been bricked.

They're produced as a standard in a length of 27 bricks tops, for light openings of maximum 6,240 mm.

They're used for fronts and back-up masonry, where a composed brick lintel didn't provide enough support

27/2 x 17 cm (27/2B)*-masonry beams

Produced with an extruder, or machine-processed ”hand-made bricks”.

Machine-processed ”hand-made” brick beams for visible masonry are always produced of brick of the same part, with which the front has been bricked.

They're produced as a standard in a length of 27 bricks tops, for light openings of maximum 6,240 mm.

They're used for fronts and back-up masonry, where a composed brick lintel didn't provide enough support

29/2 x 17 cm (29/2B)*-masonry beams

Produced with an extruder, or machine-processed ”hand-made bricks”.

Machine-processed ”hand-made” brick beams for visible masonry are always produced of brick of the same part, with which the front has been bricked.

They're produced as a standard in a length of 27 bricks tops, for light openings of maximum 6,240 mm.

They're used for fronts and back-up masonry, where a composed brick lintel didn't provide enough support.

* The first letter/The first number between brackets is the width of the lowest layer.

The second letter/The second number means the width of the respective layer.

N: The width of a brick in Danish normal format, 11 cm.

W: The width of a wide brick in Danish normal format, 17 cm.

H: The length of a brick in Danish normal format, 23 cm.

The beams may be produced with movable reinforcement. The calculation always means that it can bear the total load.

Please be careful: You must specify the type of bracing and the start direction (right/left) when you order.

For technical information and calculations please contact:

Carlsberg Bjælker A/S

E-mail carlsberg@randerstegl.dk

Phone: +45 87 11 45 11

Fax: +45 87 11 45 10